MBR TREATMENT VS CONVENTIONAL AERATION TREATMENT

MBR Treatment vs. Conventional Aeration Treatment in Sewage Treatment Plants (STPs)

The growing need for efficient and sustainable wastewater management has driven significant advancements in sewage treatment technologies. Among these, Membrane Bioreactor (MBR) Treatment and Conventional Aeration Treatment are widely used methods. While both aim to treat wastewater effectively, they differ significantly in terms of process efficiency, treatment quality, and operational aspects. Below is a comparative analysis of these two technologies.

1. Overview of the Technologies

Membrane Bioreactor (MBR) Treatment

MBR combines biological treatment with membrane filtration, using ultra-filtration or microfiltration membranes to separate solids from liquids. The membranes provide a physical barrier that ensures high-quality treated water.

Conventional Aeration Treatment

This method relies on biological treatment through activated sludge processes, where aeration tanks supply oxygen to promote microbial activity. Settling tanks (clarifiers) are used to separate sludge from treated water.

2. Key Comparison Parameters

a. Treatment Efficiency

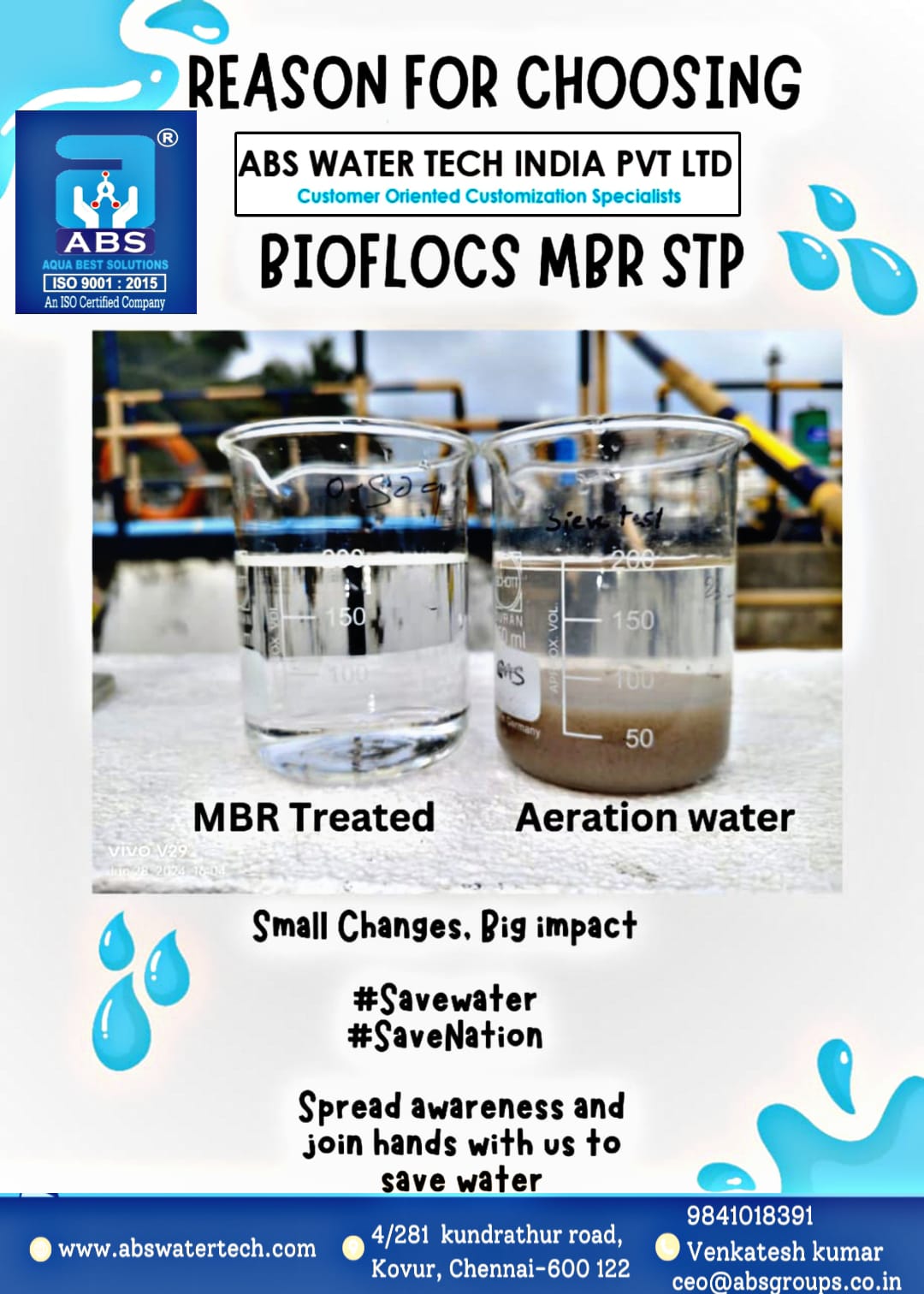

- MBR: Provides superior treatment quality, removing suspended solids, organic matter, and pathogens with a very low turbidity level (< 0.1 NTU).

- Conventional Aeration: Though effective, it may not achieve the same level of clarity and pathogen removal, often requiring additional filtration or disinfection.

b. Space Requirements

- MBR: Compact system due to the elimination of secondary clarifiers and reduced footprint of aeration tanks. Suitable for space-constrained areas.

- Conventional Aeration: Requires larger tanks and clarifiers, making it less ideal for facilities with limited space.

c. Treated Water Reuse Potential

- MBR: Produces high-quality effluent suitable for direct reuse in non-potable applications like irrigation, cooling, and flushing without additional polishing.

- Conventional Aeration: Effluent may need further treatment before reuse, increasing operational complexity and cost.

d. Sludge Management

- MBR: Generates less sludge due to higher biomass concentration, reducing the frequency and cost of sludge disposal.

- Conventional Aeration: Produces more sludge, requiring more frequent handling and disposal.

e. Energy Consumption

- MBR: high-quality output often justifies the cost.

g. Capital and Operating Costs

- MBR: Higher initial capital investment due to advanced membrane technology, but operational costs are optimized through energy efficiency and reduced sludge management needs.

- Conventional Aeration: Lower upfront cost but higher lifecycle costs due to frequent sludge handling and additional treatment for reuse applications.

h. Durability and Lifespan

- MBR: Membranes have a finite lifespan and need periodic replacement, though modern membranes offer durability of 7–10 years.

- Conventional Aeration: Equipment like blowers and clarifiers has a longer lifespan but may require frequent maintenance.

3. Applications

- MBR: Ideal for industries and commercial buildings where space is limited, water reuse is essential, and discharge regulations are stringent (e.g., hospitals, IT parks, industrial parks).

4. Key Advantages

Advantages of MBR Treatment

- High-quality effluent suitable for reuse

- Smaller footprint and reduced sludge generation

- Compliance with strict environmental norms

5. Conclusion

While both MBR and Conventional Aeration treatments are effective in wastewater management, the choice depends on specific project requirements. MBR is ideal for advanced treatment with stringent quality standards, limited space, and reuse potential.

In summary, MBR offers a more compact, efficient, and sustainable solution, whereas conventional aeration is better suited for basic treatment at a lower upfront cost. Decision-makers must weigh these factors to select the most appropriate technology for their application.

https://www.youtube.com/watch?v=jCPQAMwXQQo&t=29s