Descaling & Cooling Tower Service

Objective Of Condenser Descaling.

- The objective of pre operational chemical cleaning and flushing is to remove debris like silt, sand , scale , iron oxide deposits welding slag’s and other contaminants that are present in a new pipe work system.

- The process of pre operational flushing and cleaning becomes more important as if these contaminants are to remain in the system then it directly effects the cooling system efficiency and reduces flow through the system.

- These contaminants also prevent formation of uniform protective passivating layers which further leads to corrosion in the system.

- Based on the above it is of paramount importance to ensure that a proper preoperational cleaning/ flushing program is carried out before the system is put into normal operation.

Cleaning/ Flushing Methods.

- Chemical cleaning and flushing of any system can be carried out using either system inline pumps or external temporary pump system.

- External temporary pump system is preferred as in line pumps can get damaged due to Contaminants present in the system pipe work.

- The chemical cleaning and flushing method is also dependent upon volume of the system as should the system under consideration be a large district cooling system then huge quantum of water is required for flushing and cleaning and the quantum of waste water generated is also large Therefore depending on the system type and volume a suitable cleaning / flushing method is adopted

METHOD OF OPERATION

GENERAL

Before startup of any pre cleaning activity the following should be considered. Ensure

following during pre-start up site visit.

ALL POINTS MENTIONED BELOW HAVE TO BE CAREFULLY FOLLOWED AND

CONFIRMED TO.

1. Check availability of supply of continuous fresh water.

2. Check availability of power and electricity.

3. Check availability of labor/ manpower( 24 hour basis).

4. Check that Dosing Pumps are installed and have adequate capacity and are in

Working conditions.

5. Check availability of chemicals required for flushing/ cleaning operation at site.

6. Check availability of disposal area/ methods.

7. Check installation work is complete.

8. Identify clearly feed and drain points.

9. Make provision for drain from lowest point.

10. Ensure that the water lines that are ready for flushing have been hydrostatically tested.

11. Check availability of safety equipments at site and ensure that the workers are trained in

Safety requirements/PPE.

12. Check operation of circulation pumps if in line pumps or temporary external pump are used.

13. Check operation of temporary feed pump for filling up of water system.

14. Check connections of temporary make up feed pumps to the water system circuit.

15. Check and identify all air vents present in the circuit.

16. Check and ensure that all equipments with close tolerances are bypassed

17. Check and ensure that all isolating valves enabling circulation in this circuit are fully open.

18. Ensure that al l precision valves are removed.

19. Ensure that the entire process of treatment is done in presence of water treatment

contractor at site.

CHEMICAL CLEANING:

- Prior to start up of chemical cleaning close all drain valves which were opened during Plain water flushing.

- Clean and reinstall all strainers.

- Dose chemicals in the system.

- The circulation pumps are switched on and will continue for a maximum period until the recorded total iron level have plateau

- After maximum period recorded total iron content level reaches a constant value.

- Notify Consultant/MEP Engineer for inspection.

- Stop circulation, & drain out the complete system.

- Collect samples for record.

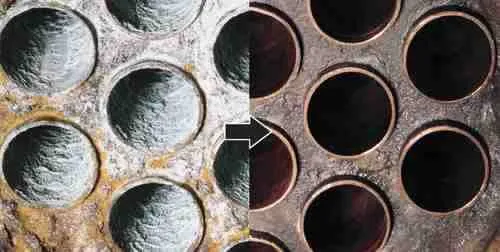

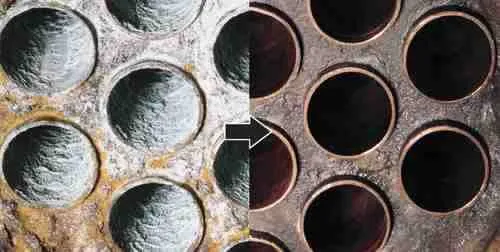

ABS 205, concentrated decaling compound is a heavy duty liquid descaling agents for removes /Cleans of scales, slime, rust and other sediments. Effective on almost all metal surfaces. Excellent for removing carbonate scales and also excess concrete from concrete mixing trucks without removing paints. Contains corrosion inhibitors to protect metal surfaces when applied. Highly economical.

This can be diluted in the Ratio of 1:10 with water.